Industrial Electro Magnetic Hammer

Price 9000 INR/ Piece

Industrial Electro Magnetic Hammer Specification

- Usage

- Industrial

- Type

- Linear

- Material

- Ms

- Product Type

- Hammer

- Voltage

- 240 Volt (v)

- Color

- Grey

- Length

- 50.8 - 76.2 Millimeter (mm)

Industrial Electro Magnetic Hammer Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 8000 Pieces Per Day

- Delivery Time

- 2 Week

- Packaging Details

- As per customer's request

- Main Domestic Market

- All India

About Industrial Electro Magnetic Hammer

The Industrial Electro Magnetic Hammer offered by us are manufactured from materials that are inherently resistant to corrosion and abrasion, with high tolerance to shocks and impacts. Primarily consisting of a stator and a rotor, these are ideal for use in innumerable industries for better maneuvering of hard to handle solid materials. The Industrial Electro Magnetic Hammer offered by us are compact, maintenance free and are far superior to other conventional hammering systems still used in various industries. One notable usage of these is for the elimination of unwanted finer particles in the inner surface of cyclone separators, spray drying plants and many more.

Additional information:

- These are resistant to weathering, i.e work flawlessly in all weather conditions

- These have optimal power efficiency, thus ensuring monetary savings to the user both in the short term as well as in the long term

- Our valuable patrons can avail these as per their requirements at market competitive rates

Specification

|

Finishing |

Polished |

|

Frequency |

50 Hz |

|

Power Source |

Electric |

|

Pulse Current (amp) |

2-6 |

|

Volt |

230 VAC |

|

Weight |

6 Kg |

FAQs

Q1. What are the benefits of using an industrial electro-magnetic hammer?

A1. An industrial electro-magnetic hammer provides many benefits such as increased production speed and efficiency, better control of the material being worked on, improved safety due to its ability to control the force and energy applied to the work surface, improved accuracy and precision in the work being performed, and the ability to easily adjust the intensity of the hammers force.

Q2. How do I know what size and type of industrial electro-magnetic hammer to use?

A2. The size and type of industrial electro-magnetic hammer needed will depend on the specific application and the material being worked on. It is important to consider the size and weight of the material, as well as the type of work being performed, before selecting the right hammer.

Q3. What safety precautions should be taken when using an industrial electro-magnetic hammer?

A3. When using an industrial electro-magnetic hammer, it is important to always wear safety glasses and protective clothing, and to ensure that the hammer is securely mounted and properly grounded.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electromagnetic Vibrator Category

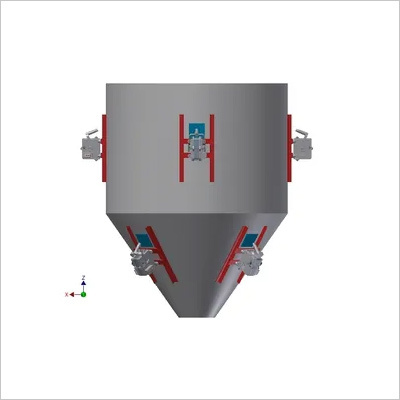

Vibrating Hopper

Price 8000.00 INR / Piece

Minimum Order Quantity : 1 , , Number

Product Type : Hopper Vibrator

Length : 7 To 20 Inch (in)

Dimension (L*W*H) : 20X5X10 Inch (in)

Usage : Industrial

Send Inquiry

Send Inquiry